Virtual implant testing

Digital verification of patient-specific implants

Trusted by

Trusted by

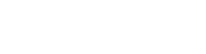

Simq VIT -Virtual Implant Testing

FDA and MDCG want medical device manufacturers to take more responsibility for custom implants.

The solution is the digital verification of custom implants. Future-proof, simple, fast and compliant with the new regulatory requirements.

Simq VIT is the first easy-to-use software for checking and optimizing the design of patient-specific implants (PSI). Increase your productivity – the predefined workflows allow you to set up complex biomechanical simulations within minutes, regardless of whether you have Computer Aided Engineering (CAE) or computer simulation skills.

By virtually applying physiological or standardized loads to a patient-specific situation, the performance and safety of patient-specific surgical implants can be verified quickly and efficiently based on objective criteria.

Faster with automated technical documentation and predefined workflows

Scalable – no additional licenses required, no limitation of users

Designers worldwide already benefit from Simq VIT

The challenge with patient-specific implants is, on the one hand, to meet all regulatory requirements and, on the other hand, to design, verify, produce and provide the surgeon with a suitable implant for the restoration in the shortest possible time in collaboration with the surgeon treating the patient.

With Simq VIT, we can incorporate safety-relevant information into the design and check it against physically tested implant variants with just a few clicks. In this way, we manage the balancing act between complying with regulatory requirements and helping patients as quickly as possible.

Thomas Kött / Head of inSilico / KLS Martin

Thomas Koett / Entwicklungsingenieur Implantate / KLS Martin

Get a free demo version of Simq VIT

Convince yourself of our virtual implant testing software

Simq VIT at a glance

Target: Test and optimize performance and safety of customized medical devices

- Digital verfication using biomechanical simulation - CAE knowledge not required

- Support surgeons decision-making in surgical planning and design process

- Physiological loadcases incl. screw and muscle forces

- Automatically generated report following FDA guidelines for your technical documentation

- Increased safety for OEM, doctor, and patient

- Selecting different workflows within the software for different implant types and anatomical regions

- Development of additional workflows within the software for manufacturer-specific implants

- Support post-market surveillance for each patient with objective data

“For us as manufacturer of Patient specific implants, simulation is the only efficient way to ensure the quality and safety of our products.”

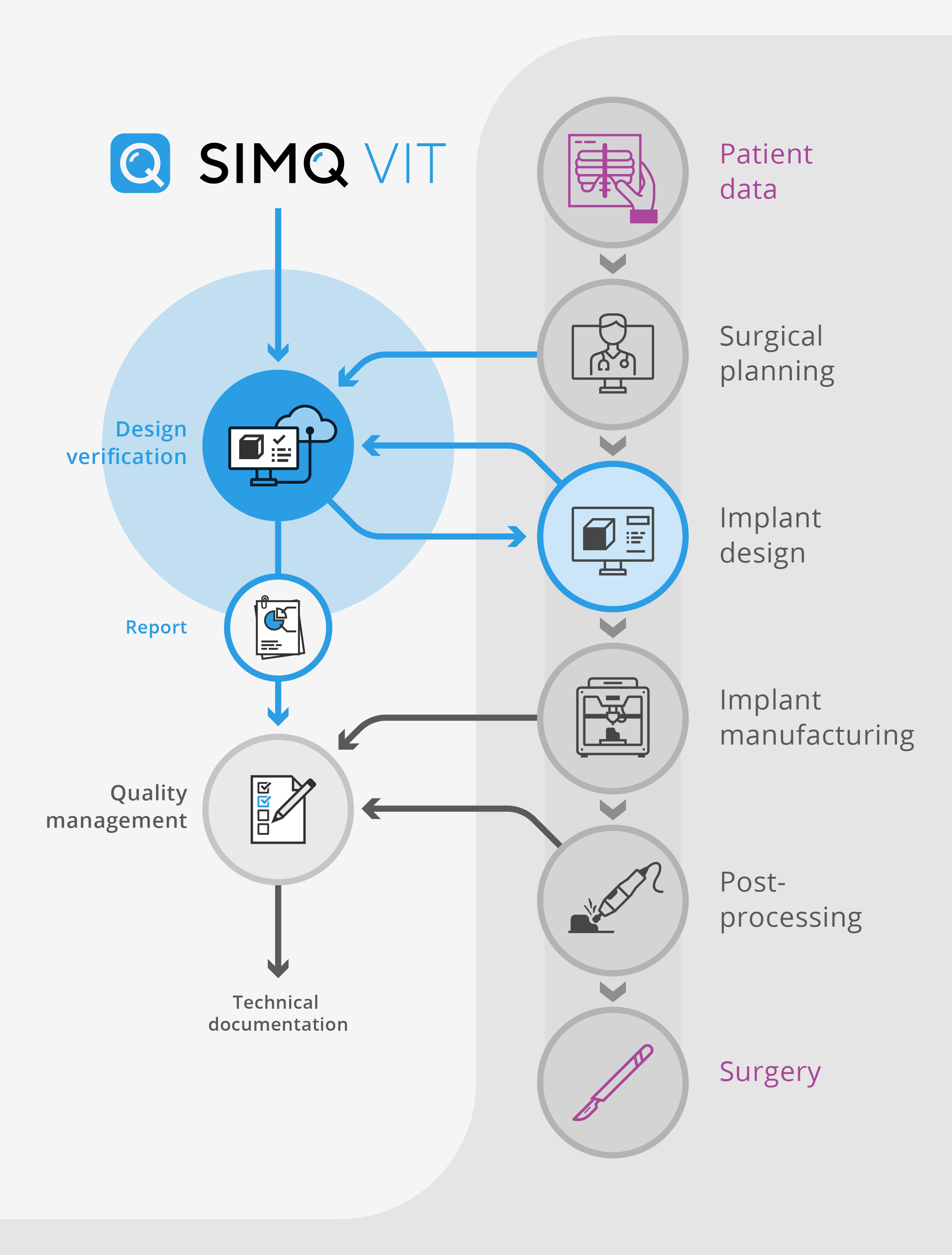

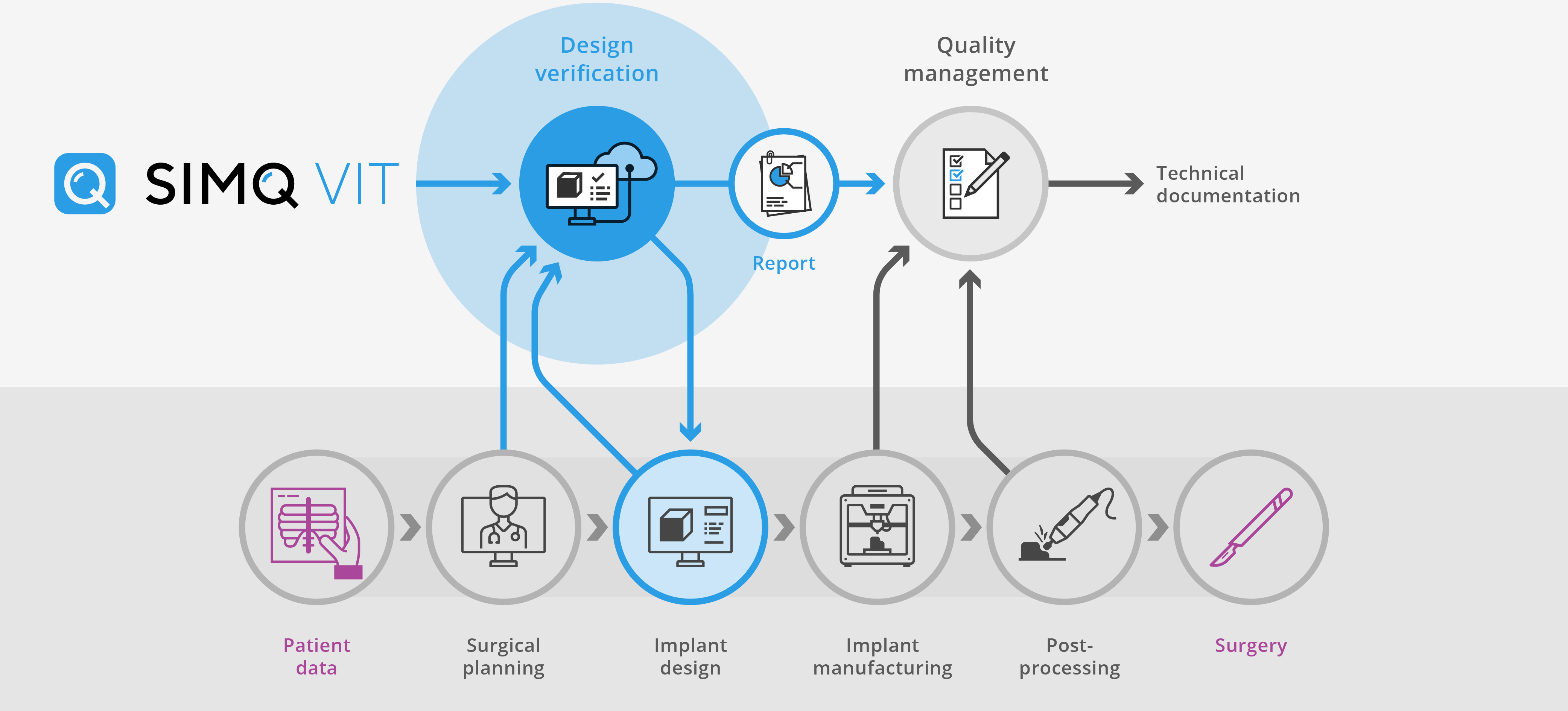

How Simq VIT works

- Efficient and compliant verification

- Objective decision-making

- Adaptable, allowing for personalized solutions

Unlocking the Power of Simq VIT for Digital verification of patient-specific implants

How it works

Simq VIT comes into play when and where decisions are made

Simq VIT at a glance

Simq VIT – selected anatomical regions

Mandible

This workflow was developed for the anatomical region of the mandible to simulate the muscle and joint reaction forces in interaction with an individual implant restoration, thus creating valuable information on strength and safety for the clinician and patient.

Thorax

Due to the very complex movements of the thorax, it was previously difficult to design necessary supplies of the bony structures with implants accurately and according to the loads.

This workflow within Simq VIT creates a solution and, at the same time, more safety for the patient.

Maxilla

Maxillary custom implants have been used successfully for many years. However, the patient-specific fabrication possible today requires close scrutiny.

Simq VIT, in conjunction with the MAXILLA workflow, was developed precisely for this purpose and answers questions regarding the strength and safety of customized restorations.

FAQs

There is a basic fee and a pay-per-use model that you can customize to suit your needs. Please contact us for more information.

Yes, we have implemented many privacy and security features (only encrypted, pseudonymized geometry data is sent to the infrastructure). Furthermore, hosting our Azure infrastructure as a “Managed Application” is possible. This means that data sovereignty always remains with our customers.

Yes, the software can be used for almost every human and animal body region.

If a customer wants a specific workflow, we can implement it and expand the library. We can perform the V&V for the models together with the customer or ourselves. We are currently working on implementing workflows for dentistry, mandibular pre-prosthetics, hand orthotics, and TMJ.

Simq VIT supports the design process of implants and is not a medical device. With our FDA-compliant report, which is always adapted to the latest changes, the technical documentation of our customers is always up to date.